HSSE txoj kev kais dej dov kais M UNC UN sib sau kais rau roj lim

Qhov tseeb thiab qhov zoo

Chip dawb machining

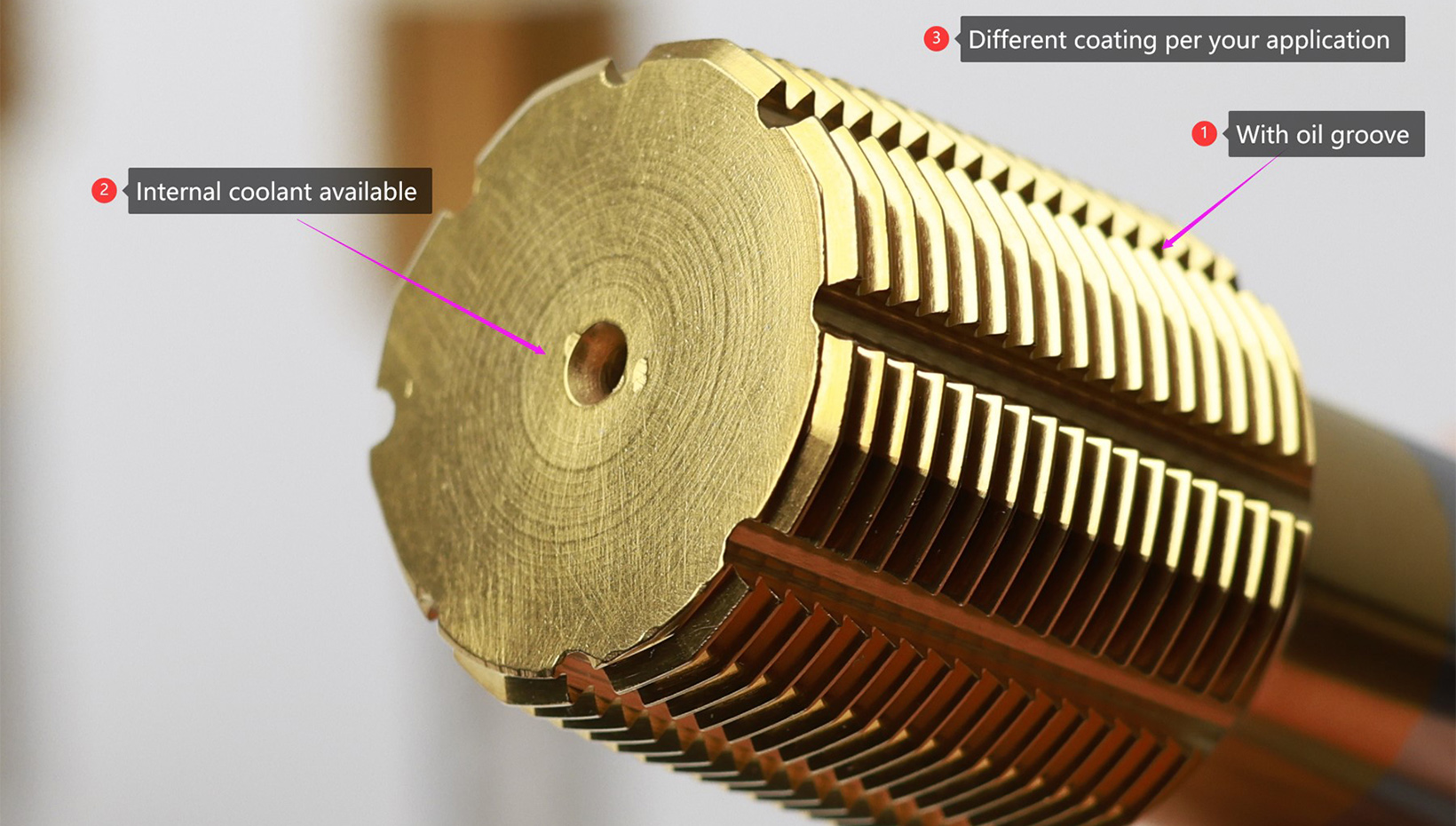

Haum rau ob qho tib si qhov muag tsis pom thiab los ntawm lub qhov xov nrog ib qho cuab yeej

Stable peformance ntawm threading, raws li tsis muaj flutes yuav tsum tau

Yuav siv tau nyob rau hauv tag nrho cov ntaub ntawv formable

Lub neej ntev lub cuab yeej ua tsaug rau cov geometry tshiab thiab txheej

Cov khoom siv raw

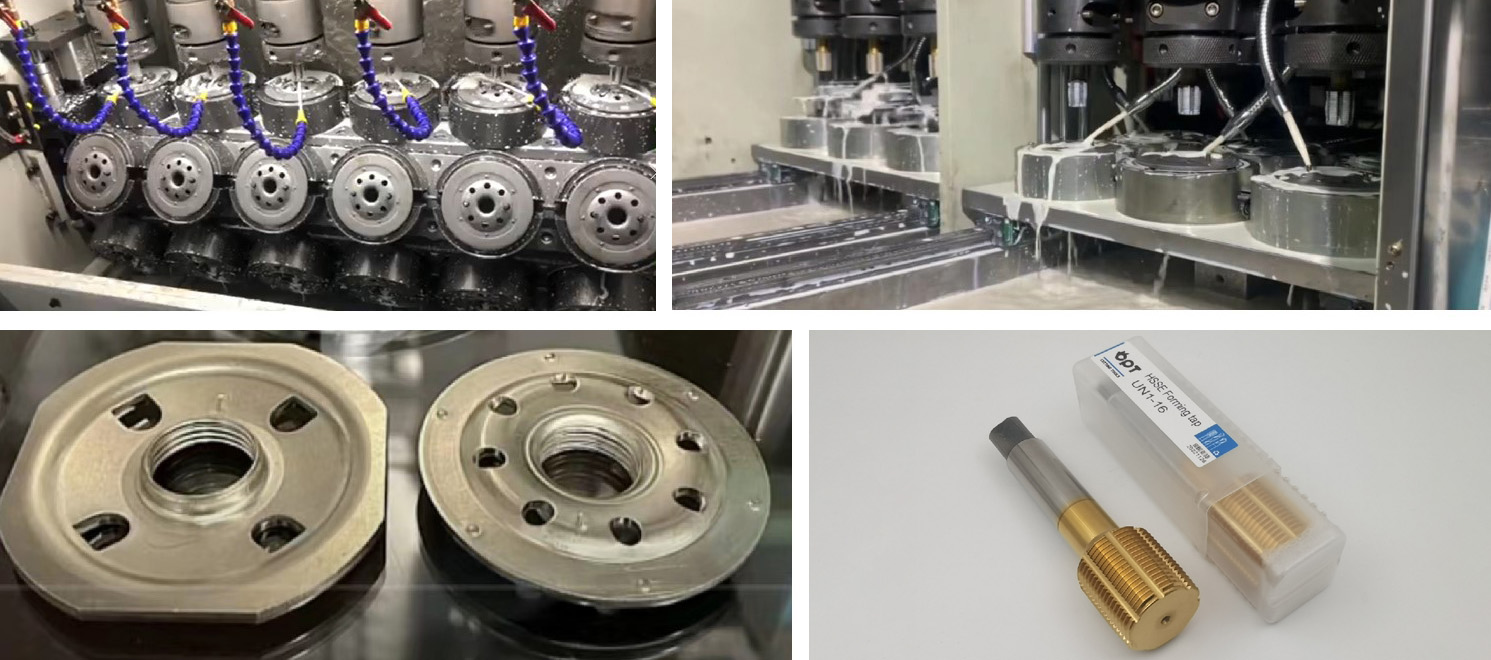

HSSE tsim cov kais dej nrog cov kab nruab nrab thiab loj sab nraud yog dav siv hauv cov roj lim ua cov nroj tsuag, kev lag luam cua fais fab thiab kev lag luam loj cav.Piv nrog HSS cov kais dej zoo tib yam, kev txhim kho ntawm cov xov tiav thiab kev ua tiav zoo heev txhim kho kev sib tw ntawm cov neeg siv khoom.Nrog rau txheej txheej, cuab yeej lub neej tuaj yeem txhim kho los ntawm ze li ntawm 10 npaug, tus nqi-kev ua tau zoo tuaj yeem txhim kho tau zoo, uas tau qhuas los ntawm cov neeg siv khoom.

Peb siv preimium cobalt cov ntaub ntawv los xyuas kom meej stability ntawm cov khoom los ntawm raw cov ntaub ntawv

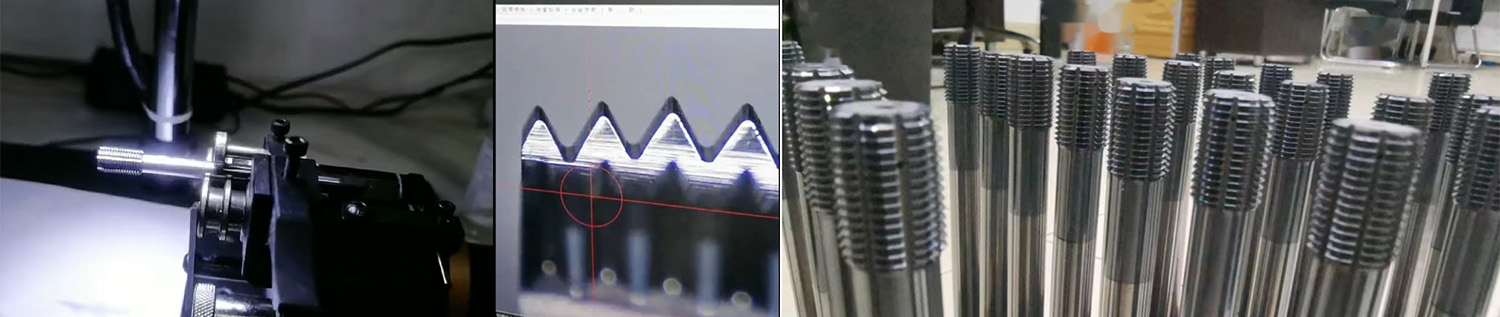

Muab cov txheej txheem tsim nyog raws li cov khoom siv ua haujlwm.Ua tsaug rau high precesion xov sib tsoo khoom kom paub tseeb tias ruaj khov zoo rau peb cov khoom.

| Metric forming taps | UN Forming taps | ||

| M12 * 1.5 | m26x 2 | UNF3/4-16 | UN 1-1/4-12 |

| M14 * 1.5 | m27x 2 | UNF1-12 | UNF1-1/2-12 |

| M16 X 1.5 | M28 X 1.5 | UN 1-14 | UNF1-1/2-16 |

| M18X1.5 | M30X1.5 | UN 1-16 | UN718-14 |

| M18x 2 | M32 X 1.5 | UN 11/16-16 | UN 2-1/4-12 |

| M20 X 1.5 | M36X1.5 | UN 13/16-16 | G3/4 |

| M22 X 1.5 | M38x1.5 | UN 13/16-18 | G1-1/4 |

| M24 × 1.5 | M39x1.5 | UN 1-1/16-12 | UN 1-5/8-12 |

| M24x 2 | M40X1.5 | UN 1-1/8-16 | UN 1-3/4-16 |

| M25X1.5 | M41x1.5 | UN 1-3/8-16 | |

| M26 X 1.5 | |||

Maching los ntawm qhov.

Yog tias qhov muag tsis pom, pls qhia rau peb paub ua ntej txhawm rau kho kom haum koj daim ntawv thov.

Xav paub ntau ntxiv, pls hu rau peb kom nug.