Nrog rau txoj kev loj hlob ntawm kev tshawb fawb thiab thev naus laus zis niaj hnub no, ntau thiab ntau cov khoom siv engineering nrog cov hardness siab yog siv, thaum cov tsoos tig thev naus laus zis tsis muaj peev xwm lossis tsis tuaj yeem ua tiav ntawm qee cov ntaub ntawv siab hardness txhua.Coated carbide, ceramics, PCBN thiab lwm yam khoom siv superhard muaj qhov kub thiab txias hardness, hnav tsis kam thiab thermochemical stability, uas muab cov txheej txheem yooj yim tshaj plaws rau kev txiav cov ntaub ntawv hardness siab, thiab tau ua tiav cov txiaj ntsig tseem ceeb hauv kev tsim khoom.Cov khoom siv los ntawm cov cuab yeej superhard thiab nws cov qauv cuab yeej thiab cov geometric tsis yog cov ntsiab lus tseem ceeb kom paub txog kev hloov nyuaj.Yog li ntawd, yuav ua li cas xaiv cov cuab yeej superhard thiab tsim cov cuab yeej tsim nyog thiab geometric tsis yog qhov tseem ceeb heev kom ua tiav qhov nyuaj tig!

(1) Coated cemented carbide

Siv ib lossis ntau txheej ntawm TiN, TiCN, TiAlN thiab Al3O2 nrog zoo hnav tsis kam ntawm cemented carbide cov cuab yeej nrog zoo toughness, thiab lub thickness ntawm txheej yog 2-18 μ m.Cov txheej txheej feem ntau muaj qis dua thermal conductivity dua li cov cuab yeej substrate thiab cov khoom siv ua haujlwm, uas ua rau cov thermal nyhuv ntawm cov cuab yeej substrate tsis muaj zog;Ntawm qhov tod tes, nws tuaj yeem txhim kho kev sib txhuam thiab adhesion hauv cov txheej txheem txiav thiab txo cov tiam ntawm kev txiav cov cua sov.

Txawm hais tias PVD txheej qhia tau hais tias muaj ntau qhov zoo, qee cov txheej txheem xws li Al2O3 thiab pob zeb diamond zoo li siv CVD txheej tshuab.Al2O3 yog ib hom txheej uas muaj zog tiv thaiv tshav kub thiab oxidation tsis kam, uas tuaj yeem cais cov cua sov los ntawm kev txiav los ntawm cov cuab yeej tshwj xeeb.CVD txheej tshuab kuj tseem tuaj yeem ua ke qhov zoo ntawm ntau txheej txheej kom ua tiav cov txiaj ntsig zoo tshaj plaws thiab ua tau raws li qhov xav tau ntawm kev txiav.

Piv nrog cov cuab yeej cemented carbide, coated cemented carbide cov cuab yeej tau zoo heev hauv lub zog, hardness thiab hnav tsis kam.Thaum tig lub workpiece nrog hardness ntawm HRC45 ~ 55, tus nqi qis-coated cemented carbide tuaj yeem paub qhov kev hloov ceev ceev.Nyob rau hauv xyoo tas los no, qee cov tuam ntxhab tau txhim kho kev ua haujlwm ntawm cov cuab yeej coated los ntawm kev txhim kho cov ntaub ntawv txheej thiab lwm txoj kev.Piv txwv li, qee lub tuam txhab hauv Tebchaws Meskas thiab Nyij Pooj siv Swiss AlTiN txheej txheej thiab cov txheej txheem tshiab patented thev naus laus zis los tsim cov hniav nrog cov tawv tawv kom siab li HV4500 ~ 4900, uas tuaj yeem txiav HRC47 ~ 58 tuag steel ntawm qhov ceev ntawm 498.56m / min. .Thaum tig kub txog li 1500 ~ 1600 ° C, lub hardness tseem tsis txo qis thiab tsis oxidize.Kev pabcuam lub neej ntawm cov hniav yog plaub npaug ntawm cov hniav dav dav, thaum tus nqi tsuas yog 30%, thiab qhov adhesion zoo.

(2) Cov khoom siv ceramic

Nrog rau kev txhim kho tas mus li ntawm nws cov muaj pes tsawg leeg, cov qauv thiab cov txheej txheem nias, tshwj xeeb tshaj yog kev txhim kho ntawm nanotechnology, cov khoom siv ceramic ua rau nws muaj peev xwm toughen cov cuab yeej ceramic.Nyob rau yav tom ntej, ceramics yuav ua rau lub kiv puag ncig thib peb hauv kev txiav tom qab high-speed steel thiab cemented carbide.Cov cuab yeej ceramic muaj qhov zoo ntawm qhov nyuaj siab (HRA91 ~ 95), lub zog siab (khoov lub zog 750 ~ 1000MPa), zoo hnav tsis kam, tshuaj lom neeg ruaj khov, zoo adhesion tsis kam, tsis tshua muaj kev sib txhuam coefficient thiab tus nqi qis.Tsis tas li ntawd, cov cuab yeej ceramic kuj muaj qhov kub thiab txias hardness, uas ncav cuag HRA80 ntawm 1200 ° C.

Thaum lub sij hawm ib txwm txiav, cov cuab yeej ceramic muaj qhov ua tau zoo heev, thiab nws qhov kev txiav ceev tuaj yeem yog 2 ~ 5 npaug siab dua li ntawm cov cemented carbide.Nws yog tshwj xeeb tshaj yog haum rau machining siab hardness cov ntaub ntawv, xov thiab high-speed machining.Nws tuaj yeem txiav ntau cov hlau tawv tawv thiab tawv cam khwb cia hlau nrog hardness txog HRC65.Feem ntau siv yog alumina raws li ceramics, silicon nitride raws li ceramics, cermets thiab whisker toughened ceramics.

Alumina-raws li cov cuab yeej ceramic muaj cov tawv tawv dua li cov cemented carbide.Feem ntau, txiav ntug yuav tsis tsim cov yas deformation nyob rau hauv high-ceev txiav tej yam kev mob, tab sis nws lub zog thiab toughness yog tsawg heev.Txhawm rau txhim kho nws qhov tawv thiab qhov cuam tshuam, ZrO lossis TiC thiab TiN sib tov tuaj yeem ntxiv.Lwm txoj hauv kev yog ntxiv cov hlau ntshiab lossis silicon carbide whiskers.Ntxiv nrog rau qhov siab liab hardness, silicon nitride raws li ceramics kuj muaj zoo toughness.Piv nrog alumina raws li ceramics, nws qhov tsis zoo yog tias nws yooj yim los tsim kub kub diffusion thaum machining steel, uas ua rau cov cuab yeej hnav.Silicon nitride raws li ceramics yog tsuas yog siv rau kev sib tshuam tig thiab milling ntawm grey cam khwb cia hlau.

Cermet yog ib hom carbide-raws li cov ntaub ntawv, uas TiC yog lub ntsiab nyuaj theem (0.5-2 μm) Lawv ua ke nrog Co los yog Ti binders thiab zoo ib yam li cemented carbide cov cuab yeej, tab sis lawv muaj tsawg affinity, kev sib txhuam zoo thiab zoo. hnav tsis kam.Nws tuaj yeem tiv taus qhov kub siab dua li cov pa cemented carbide, tab sis nws tsis muaj qhov cuam tshuam ntawm cemented carbide, lub toughness thaum txiav hnyav thiab lub zog ntawm qis ceev thiab pub loj.

(3) Cubic boron nitride (CBN)

CBN yog thib ob tsuas yog pob zeb diamond hauv hardness thiab hnav tsis kam, thiab muaj qhov kub thiab txias hardness.Piv nrog rau ceramics, nws cov cua kub tsis kam thiab tshuaj lom neeg ruaj khov yog me ntsis tsis zoo, tab sis nws cov kev cuam tshuam lub zog thiab kev ua haujlwm zoo dua.Nws yog dav siv rau kev txiav cov hlau tawv (HRC ≥ 50), pearlitic grey cam khwb cia hlau, chilled cam khwb cia hlau thiab superalloy.Piv nrog cov cuab yeej cemented carbide, nws cov kev txiav ceev tuaj yeem nce ntxiv los ntawm ib qho kev txiav txim ntawm qhov loj.

Cov khoom sib xyaw polycrystalline cubic boron nitride (PCBN) cov cuab yeej nrog cov ntsiab lus CBN muaj siab hardness, zoo hnav tsis kam, siab compressive zog thiab zoo cuam tshuam toughness.Nws qhov tsis zoo yog qhov tsis zoo thermal stability thiab tsis tshua muaj tshuaj lom neeg inertness.Nws yog tsim rau kev txiav cov cua kub-resistant alloys, cam khwb cia hlau thiab hlau-raws li sintered hlau.Cov ntsiab lus ntawm CBN hais nyob rau hauv PCBN cov cuab yeej yog tsawg, thiab hardness ntawm PCBN cov cuab yeej siv ceramics li binder yog tsawg, tab sis nws ua rau tsis zoo thermal stability thiab tsis tshua muaj tshuaj inertia ntawm cov khoom qub, thiab yog tsim rau txiav hardened steel.

Thaum txiav grey cam khwb cia hlau thiab cov hlau tawv tawv, cov cuab yeej ceramic lossis CBN tuaj yeem xaiv.Vim li no, tus nqi-cov txiaj ntsig thiab kev soj ntsuam zoo yuav tsum tau ua los txiav txim siab seb yuav xaiv qhov twg.Thaum txiav hardness qis dua HRC60 thiab me me pub tus nqi tau txais, cov cuab yeej ceramic yog qhov kev xaiv zoo dua.PCBN cov cuab yeej tsim nyog rau kev txiav workpieces nrog hardness siab dua HRC60, tshwj xeeb tshaj yog rau machining tsis siv neeg thiab high-precision machining.Tsis tas li ntawd, qhov kev ntxhov siab nyob ntawm qhov chaw ua haujlwm tom qab txiav nrog PCBN cov cuab yeej kuj tseem ruaj khov dua li nrog cov cuab yeej ceramic nyob rau hauv cov xwm txheej ntawm tib lub flank hnav.

Thaum siv cov cuab yeej PCBN kom qhuav txiav cov hlau tsis muaj zog, cov ntsiab lus hauv qab no yuav tsum tau ua raws: xaiv qhov loj txiav qhov tob kom deb li deb tau raws li qhov ua tau raws li qhov ua tau zoo ntawm cov cuab yeej siv lub tshuab tso cai, kom cov cua sov tsim hauv cheeb tsam txiav tuaj yeem muag. cov hlau nyob hauv pem hauv ntej ntawm ntug hauv zos, uas tuaj yeem txo qhov hnav ntawm PCBN cuab yeej.Tsis tas li ntawd, thaum siv qhov me me txiav qhov tob, nws yuav tsum tau txiav txim siab tias qhov tsis zoo thermal conductivity ntawm PCBN cuab yeej tuaj yeem ua rau cov cua sov hauv qhov chaw txiav lig dhau lawm, thiab thaj chaw shear kuj tseem tuaj yeem tsim cov txiaj ntsig zoo ntawm cov hlau, txo qis. hnav ntawm txiav ntug.

2. Hniav qauv thiab geometric tsis ntawm cov cuab yeej superhard

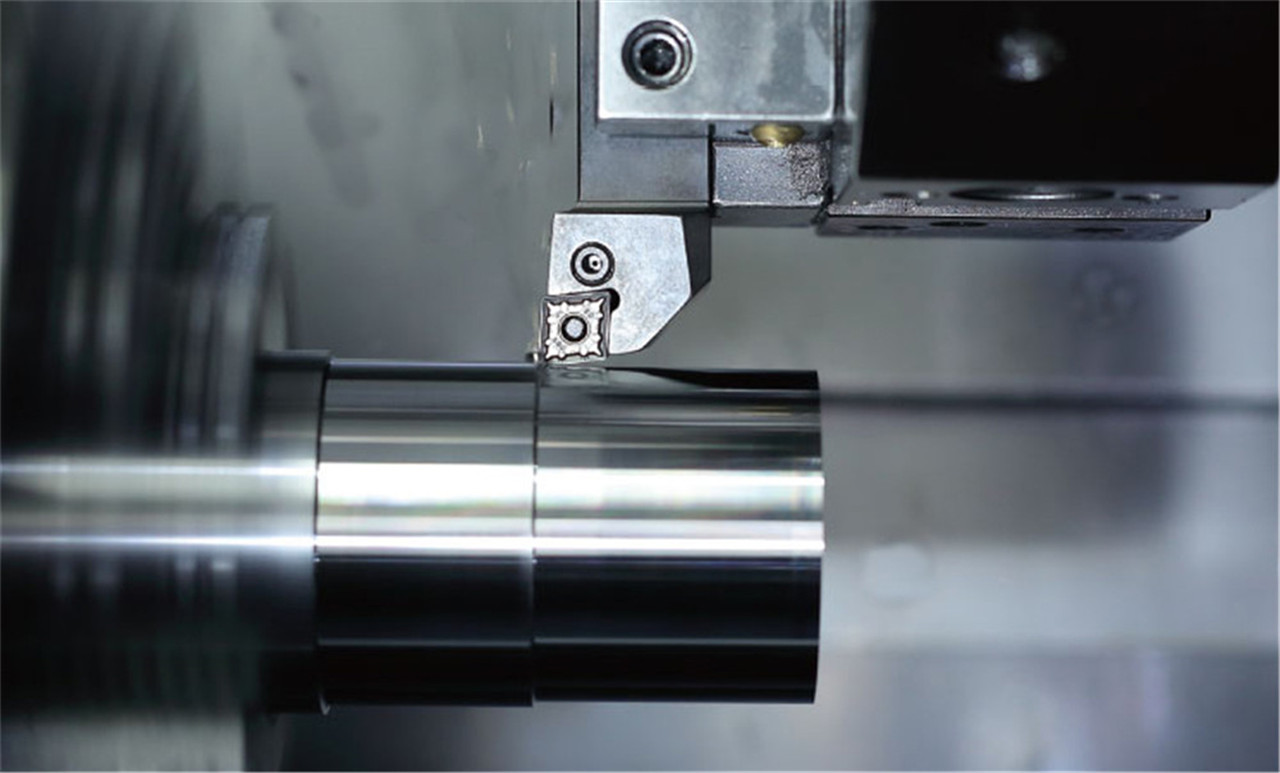

Kev txiav txim siab tsim nyog ntawm cov duab thiab cov duab geometric ntawm lub cuab yeej yog qhov tseem ceeb heev los muab kev ua si tag nrho rau kev txiav cov cuab yeej.Nyob rau hauv cov nqe lus ntawm cov cuab yeej lub zog, lub cuab tam lub zog ntawm ntau yam hniav duab los ntawm siab mus rau qis yog: puag ncig, 100 ° pob zeb diamond, square, 80 ° pob zeb diamond, daim duab peb sab, 55 ° pob zeb diamond, 35 ° pob zeb diamond.Tom qab cov khoom siv hniav raug xaiv, cov hniav zoo nkauj nrog lub zog siab tshaj plaws yuav tsum raug xaiv.Hard tig hniav yuav tsum tau xaiv kom loj li sai tau, thiab ntxhib machining yuav tsum tau ua nrog ib ncig thiab loj tip arc vojvoog hniav.Lub kaum sab xis arc yog hais txog 0.8 thaum ua tiav μ Txog m.

Lub hardened steel chips yog liab thiab mos ribbons, nrog zoo brittleness, yooj yim rau tawg thiab tsis-binding.Lub hardened steel txiav nto yog cov zoo thiab feem ntau tsis tsim nti tsub zuj zuj, tab sis lub txiav quab yuam yog loj, tshwj xeeb tshaj yog lub radial txiav quab yuam yog loj tshaj lub ntsiab txiav quab yuam.Yog li, lub cuab yeej yuav tsum siv lub kaum sab xis tsis zoo (mus ≥ - 5 °) thiab lub kaum sab xis loj (ao = 10 ° ~ 15 °).Lub ntsiab deflection lub kaum sab xis nyob ntawm qhov rigidity ntawm lub tshuab cuab yeej, feem ntau 45 ° ~ 60 °, kom txo tau lub chatter ntawm lub workpiece thiab cov cuab yeej.

Post lub sij hawm: Feb-24-2023