Xov milling cuttersthiab cov kais dej yog ob qho tib si siv rau machining threads, tab sis lawv cov qauv thiab kev siv sib txawv heev.Xov milling cutters yog tsim rau batch ua, nrog high efficiency tab sis tsawg dua qhov tseeb;Kais yog tsim rau ib tug neeg thiab me me batch hnyav ntau lawm, nrog cov neeg siab tab sis tsis tshua muaj efficiency.Kab lus no muab cov ncauj lus kom ntxaws sib piv ntawm ob cov cuab yeej no los ntawm ntau qhov kev xav, suav nrog cov qauv, kev siv, qhov zoo thiab qhov tsis zoo, txhawm rau muab cov neeg nyeem siv siv los xaiv cov cuab yeej raug.

1. Cov qauv kev sib piv

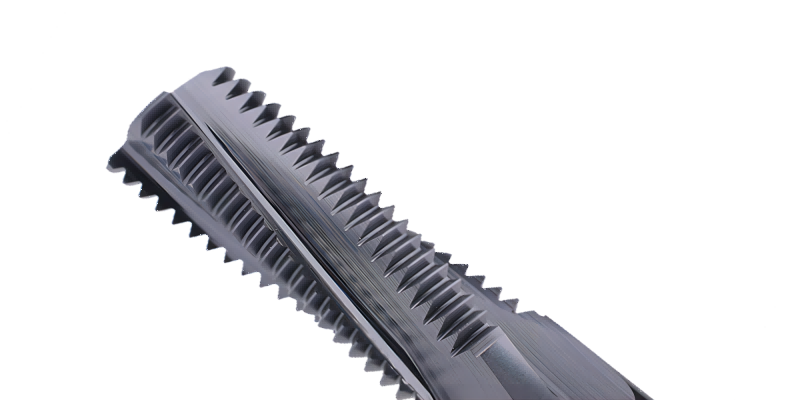

Tus qauv ntawmxov milling cutteryog los carve cov duab uas ua raws li cov xov specification thiab geometric duab ntawm lub milling cutter, thiab ces siv lub tshuab milling los ua cov threaded qhov ntawm tej yam specification.Cov kais dej yog siv los txiav cov xov uas ua tau raws li cov lus qhia tshwj xeeb thiab cov duab geometric ntawm lub voj voog sab nrauv lossis sab hauv lub qhov geometry.Nws yog siv manually lossis mechanically.Los ntawm qhov no, nws tuaj yeem pom tias tus yam ntxwv ntawm cov xov milling cutter yog tsim rau ntau lawm, thaum lub kais dej yog tsim rau tus neeg ua haujlwm.

2.Kev sib piv hauv kev siv

Kev siv axov milling cutteryuav tsum tau txhawb lub workpiece ntawm lub tshuab milling thiab machining ib tug specification ntawm threaded qhov siv kauv txiav.Thaum ua threaded qhov, qhov ntau dua qhov kev ncua deb ntawm lub cuab yeej thiab qhov chaw txiav, qhov raug qis dua.Vim tsis muaj peev xwm ntawm covxov milling cutterTxhawm rau txiav cov kab uas hla sab nraud, nws yog ib qho tsim nyog yuav tsum tau siv cov cuab yeej sab nraud thaum ua cov kab kab uas hla ntawm cov xov.Kev siv xov milling cutters tuaj yeem txhim kho kev ua haujlwm zoo, tab sis qhov tseeb yog me ntsis qis dua.Cov kais dej yog siv los txiav cov xov uas ua tau raws li qhov tshwj xeeb thiab cov duab geometric hauv lub qhov.Lub txiav quab yuam ntawm tus kais yog me me, thiab ib txoj xov yog manually ua, uas tuaj yeem ua cov txheej txheem sab nraud thiab aperture ntawm xov.Vim kev ua haujlwm ntawm phau ntawv, qhov tseeb machining yog siab, tab sis qhov ua tau zoo yog tsawg.

3.Kev sib piv ntawm qhov zoo thiab qhov tsis zoo

Qhov zoo ntawmxov milling cuttersyog: high processing efficiency, haum rau loj ntau lawm.

Qhov tsis zoo yog qhov tseeb yog me ntsis qis, thiab nws tsis tuaj yeem ua cov xov me me aperture thiab cov xov sab nraud.

Qhov zoo ntawm kais yog: siab machining raug, haum rau me me batch ntau lawm.

Qhov tsis zoo yog: kev ua haujlwm qis, tsuas yog tsim nyog rau kev ua cov xov me me.

4.Kev sib piv ntawm kev siv scenarios

Xov milling cuttersyog tsim rau batch zus tau tej cov loj-loj threaded qhov.Kev siv xov milling cutters tuaj yeem txhim kho kev tsim khoom thiab ua kom luv luv.Cov kais dej tsim nyog rau kev ua cov khoom me me thiab qhov ntau thiab tsawg ntawm cov xov, thiab tsim nyog rau kev tuav thiab kev siv tshuab.

Post lub sij hawm: Lub Xya hli ntuj-24-2023