Carbide Kauj Ruam Rau Stainless Hlau Thiab Txhuas

Daim ntawv thov khoom

Zoo adhesion ntawm txheej thiab substrate ua kom muaj kev ruaj ntseg thiab ua kom lub neej ntev

Cov txheej txheej du du txo qhov kev txiav tsis kam thiab txhim kho cov cuab yeej hnav tsis kam

Haum rau: Hlau, stainless hlau, txhuas, cam khwb cia hlau thiab siab tawv steel, Dav siv nyob rau hauv aerospace, tsheb tsim, xov tooj ntawm tes tsim, nti ntim thiab lwm yam lag luam.

Khoom zoo

OPT yog txawv: ib tug pioneer hauv technology thiab innovation rau ntau tshaj 25 xyoo.

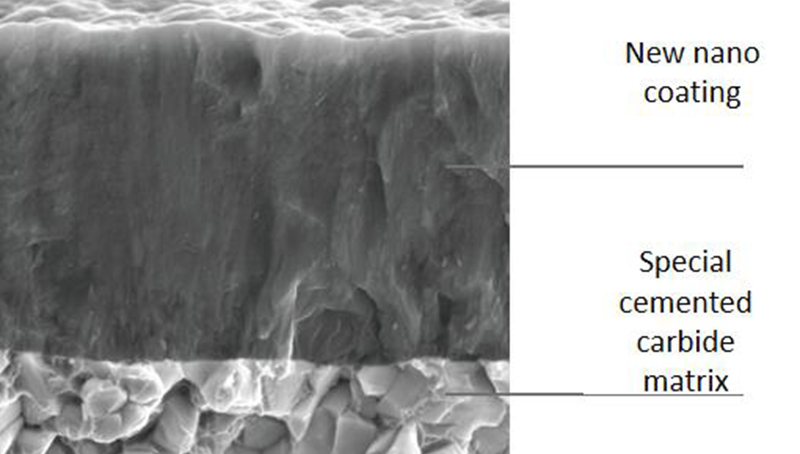

Cov txheej siv los ntawm OPT yog 40% muaj zog dua li cov txheej txheem zoo tib yam.

Tshiab "nanostructure" txheej tshuab yog saws, thiab txheej txheej yog compact.

Zoo heev adhesion ntawm txheej thiab substrate ua kom muaj kev ruaj ntseg thiab ua kom lub neej ntev.

Cov txheej txheej du du txo qhov kev txiav tsis kam thiab txhim kho cov cuab yeej hnav tsis kam.

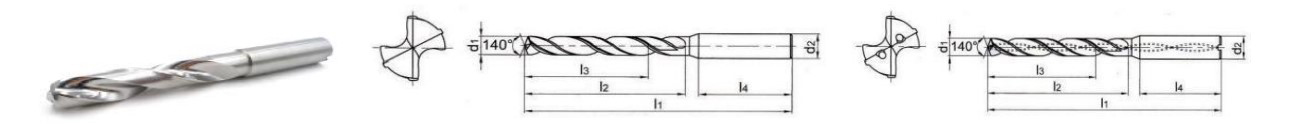

1.Lub ntsis ntawm cov carbide yog ib qho yooj yim tawg

2.Qhov taw tes yog drilled nrog ib tug reinforced tungsten steel ntsis

Koj tuaj yeem siv cov cuab yeej tsim tshwj xeeb uas siv los ntawm cov kws tshaj lij

Technology qhia koj cov kws tshaj lij tsim khoom.Koj tseem tuaj yeem qhia peb koj cov kev xav tau, peb lub tuam txhab muab koj cov kev daws teeb meem tag nrho

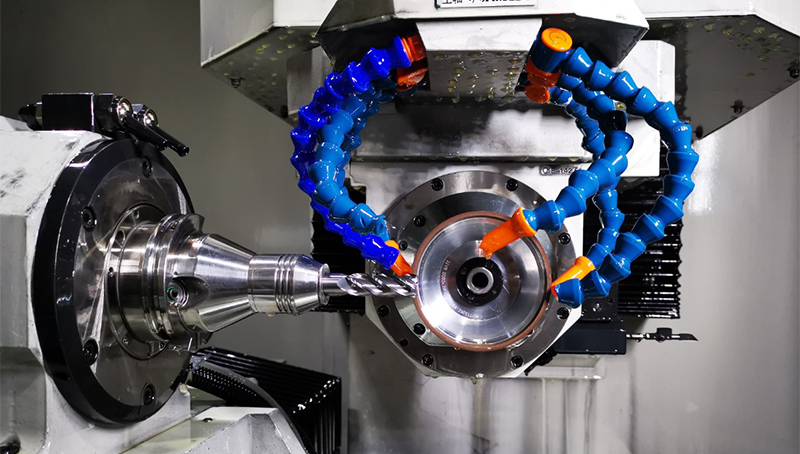

Zoo heev groove tuav

Cov txheej txheem kev ua haujlwm siab yog siv los kho qhov ua tiav ntawm qhov zawj thiab cov hlau chute, uas txo qhov kev txiav tsis kam ntawm cov hlau me ntsis thiab tuaj yeem tso cov hlau chute sai dua, yog li txo cov cua sov ntawm lub cuab yeej thiab txhim kho lub neej ntawm me ntsis.

Kev txhawj xeeb-dawb lub neej warranty

Yog tias koj cov cuab yeej nyuaj alloy xav tau kev sib tsoo, koj tuaj yeem nrhiav tau peb rau kev sib tsoo, tib lub sijhawm rau peb cov cuab yeej yuav muab kev pab cuam tom qab muag, muaj teeb meem ntawm cov cuab yeej lossis cov teeb meem ntau lawm, peb yuav muab kev pabcuam 24 teev thiab daws!

Peb yog cov kws tshaj lij kev cai cutter chaw tsim tshuaj paus

Tungsten carbide bur PRODUCTION PROCESS

Kauj Ruam 1: Siv cov khoom siv raw zoo

Kauj ruam 2: Profile sib tsoo

Peb lub Hoobkas tsim cov khoom siv sib tsoo tungsten steel CNC sib tsoo tshuab, kais sib tsoo tshuab, CNC sib tsoo tshuab sib tsoo reamer thiab milling cutter, tau kawg, muaj ntau yam kev tsim thiab tsim cov neeg ua haujlwm.

| ntsis taub Qhov siab: d1 (m7) | Drilling qhov sib piv (1 / d) | Txias hom | Shank daim ntawv | Ordering qauv | Qhov loj me (mm) | lus hais | ||||

| Shank txoj kab uas hla | Tag nrho ntev | Qhov ntev | Pom zoo drilling qhov tob | txheej | ||||||

| d2 (h6) | 11 | 12 | 13 | |||||||

| 2 ~ 2.5 hli | 3 | Kev txias sab nraud | Ncaj shank | d113 * d2 * 11 * 3D | 3 | 58 | 13 | 9 | ||

| 5 | Kev txias sab nraud | Ncaj shank | d1 * 13 * d2 * l1 * 5D | 3 | 58 | 18 | 14 | |||

| 2.55-2.95 Nws | 3 | Kev txias sab nraud | Ncaj shank | d113 * d2 * 11 * 3D | 4 | 58 | 13 | 9 | ||

| 5 | Kev txias sab nraud | Ncaj shank | d1 * 13 * d2 * 11 * 5D | 4 | 58 | 18 | 14 | |||

| 3 ~ 3.5 | 3 | Kev txias sab nraud | Ncaj shank | d1 * 13 * d2 * 11 * 3D | 4 | 62 | 20 | 14 | ||

| 5 | Kev txias sab nraud | Ncaj shank | d1 * 13 * d2 * 11 * 5D | 4 | 66 | 28 | 23 | |||

| 3.6 ~ 4 | 3 | Kev txias sab nraud | Ncaj shank | d1 * 13 * d2 * 11 * 3D | 4 | 58 | 20 | 14 | ||

| 5 | Kev txias sab nraud | Ncaj shank | 113 * d2 * 11 * 5D | 4 | 66 | 28 | 23 | |||

| 8 | Internal txias | Ncaj shank | d1 * 13 * d2 * l1 * 8D | 4 | 72 | 34 | 29 | |||

| 4-4.9 Nws | 3 | Kev txias sab nraud | Ncaj shank | d113 * d2 * 11 * 3D | 5 | 66 | 24 | 17 | ||

| 5 | Kev txias sab nraud | Ncaj shank | d1 * 3 * d2 * 11 * 5D | 5 | 74 | 34 | 26 | |||

| 8 | Internal txias | Ncaj shank | d113 * d2 * 11 * 8D-C | 6 | 95 | 57 | 46 | |||

| 5-6.0 Nws | 3 | Kev txias sab nraud | Ncaj shank | d1 * 13 * d2 * 11 * 3D | 6 | 66 | 28 | 20 | ||

| 5 | Kev txias sab nraud | Ncaj shank | d1 * 13 * d2 * 11 * 5D | 6 | 82 | 42 | 32 | |||

| 8 | Internal txias | Ncaj shank | d1 * 13 * d2 * I1 * 8D-C | 6 | 95 | 57 | 47 | |||

Cov ntaub ntawv siv tau ntawm cov khoom ua tiav

| tus lej | Cov ntaub ntawv ua tiav | |||||||||

| Cov hlau me me HB≤ 180 | Carbon thiab alloy hlau | Pre hardened steel, hardened steel | stainless hlau | nrum hlau | Hlau hlau | aluminium alloy | kub- tawm tsam tag nrho | |||

| ~ 40 HRC | ~ 50 HRC | ~ 60 HRC | ||||||||

Lus ceeb toom:

1.Yog hais tias lub 3 los yog 5 lub sij hawm xyaum me ntsis xav tau kev txias sab hauv, thov sau ntawv thaum txiav txim, ua raws li C;

2.Qhov kov yog ncaj nraim los ntawm lub neej ntawd.Yog tias koj xav tau lwm yam qauv, thov xa mus rau peb cov ntaub ntawv tuav lossis kos duab rau kev pom zoo;3.Lub neej ntawd sab saum toj kaum yog 140 degrees.Yog tias xav tau lwm cov ces kaum, thov kos lossis xa mus rau daim duab;

4.Yog tias qhov kev txiav txim tsis sib haum nrog peb lub tuam txhab, koj tuaj yeem qhia peb cov neeg ua haujlwm pabcuam, thiab peb yuav txaus siab los muab cov duab kos rau kev pom zoo rau koj;

5. Lub cutter tsis coated los ntawm lub neej ntawd.Yog xav tau txheej, thov qhia koj cov kev xav tau lossis cov ntaub ntawv ua tiav.