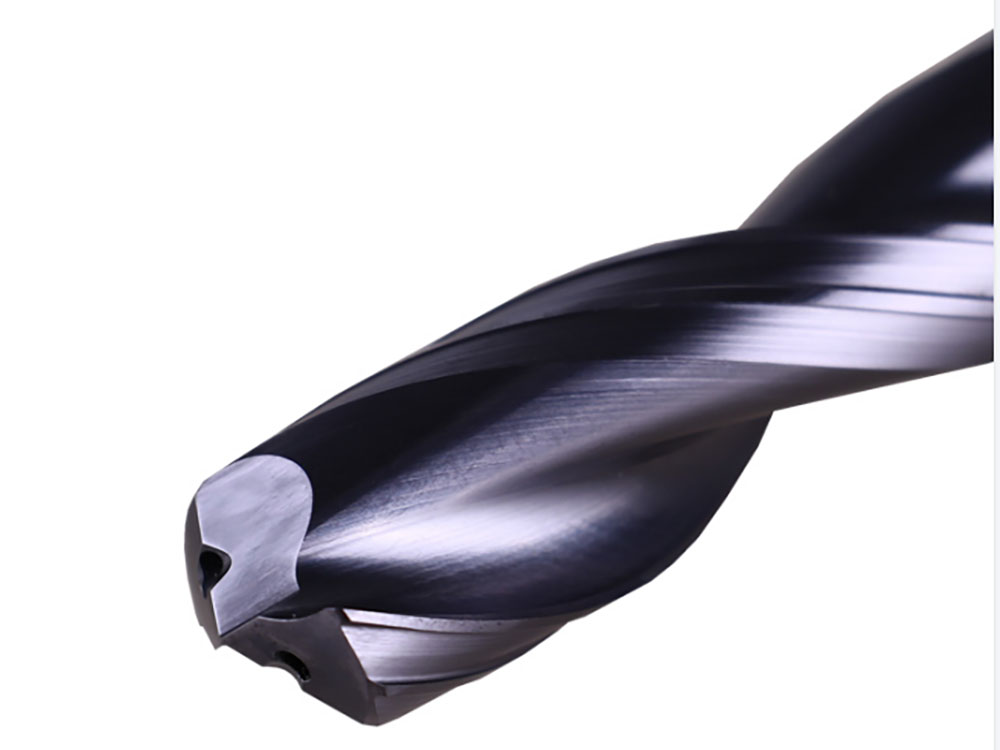

Internally txias laum ntsis rau qhov sib sib zog nqus qhov machining

Khoom zoo

Piv nrog rau qhov tsawg dua qhov sib sib zog nqus, qhov sib sib zog nqus qhov txias thiab cov hlau tshem tawm yog qhov nyuaj.Nws yog ib qho tsim nyog los tswj kev tawg ntawm cov khoom siv hlau, tab sis kuj yuav tsum tswj cov dhia dhia thiab kev ruaj ntseg ntawm cov cuab yeej, txwv tsis pub lub cuab yeej yooj yim tawg riam los yog lub qhov tsis ncaj.

Tus qauv sib sib zog nqus qhov laum me ntsis: Haum rau qhov sib sib zog nqus qhov machining ntawm steel, cam khwb cia hlau thiab lwm yam ntaub ntawv

| Ntsis txoj kab uas hla d1 (m7) | Drilling qhov tob ratio (1/d) | Txias hom | Shank daim ntawv | Ordering qauv | Qhov loj me (mm) | lus hais | ||||

| Txoj kab uas hla | Tag nrho ntev | Qhov ntev | Pom zoo drilling qhov tob | txheej | ||||||

| d2 (h6) | l1 | 12 | 13 | |||||||

| 3 ~ 3.5 hli | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 6 | 90 | 50 | 40 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 6 | 123 | 83 | 72 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 6 | 160 | 120 | 108 | |||

| 3.6 ~ 4 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 6 | 90 | 50 | 40 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 6 | 136 | 96 | 84 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 6 | 176 | 136 | 124 | |||

| 4.1 ~ 4.5 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 6 | 102 | 64 | 56 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 6 | 148 | 108 | 96 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 6 | 192 | 152 | 140 | |||

| 4.6-4.9 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 6 | 102 | 64 | 56 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 6 | 158 | 118 | 106 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 6 | 208 | 168 | 156 | |||

| 5.0 ~ 5.5 hli | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 6 | 116 | 78 | 72 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 6 | 168 | 128 | 116 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 6 | 228 | 188 | 170 | |||

| 5.6 ~ 6.0 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 6 | 116 | 78 | 72 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 6 | 180 | 140 | 126 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 6 | 240 | 200 | 182 | |||

| 6.1 ~ 6.5 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 8 | 131 | 93 | 82 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 8 | 190 | 150 | 132 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 8 | 260 | 220 | 202 | |||

| 6.6 ~ 7 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 8 | 131 | 92 | 83 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 8 | 202 | 160 | 143 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 8 | 270 | 230 | 213 | |||

| 7.1-7.5 Nws | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 8 | 145 | 108 | 95 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 8 | 213 | 172 | 155 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 8 | 290 | 250 | 230 | |||

| 7.6 ~ 8 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 8 | 146 | 108 | 96 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 8 | 223 | 183 | 163 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 8 | 305 | 263 | 245 | |||

| 8.1-8.5 Nws | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 10 | 160 | 120 | 107 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 10 | 239 | 195 | 175 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 10 | 330 | 285 | 263 | |||

| 8.6-9.0 Nws | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 10 | 162 | 120 | 108 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 10 | 249 | 205 | 185 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 10 | 340 | 295 | 276 | |||

| 9.1-9.5 Nws | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 10 | 174 | 131 | 120 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 10 | 262 | 217 | 195 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 10 | 360 | 315 | 291 ib | |||

| 9.6—10 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 10 | 174 | 132 | 120 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 10 | 272 | 228 | 206 | |||

| 30 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 30D | 10 | 372 ib | 328 | 305 | |||

| 10.1-10.5 Nws | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 12 | 204 | 156 | 144 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 12 | 292 ib | 242 | 220 | |||

| 10.6—11 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 12 | 204 | 156 | 144 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 12 | 300 | 250 | 228 | |||

| 11.1 ~ 12 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 12 | 204 | 156 | 144 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 12 | 325 | 275 | 250 | |||

| 12-13 : kuv | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 14 | 230 | 182 | 168 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 14 | 338 | 290 | 265 | |||

| 13.1-14.13 Nws | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 14 | 230 | 182 | 168 | ||

| 20 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 20D | 14 | 367 ib | 318 | 290 | |||

| 14.1-16 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 14 | 260 | 208 | 194 | ||

| 16.1—18 | 12 | Internal txias | Ncaj shank | d1 * l3 * d2 * l1 * 12D | 14 | 286 | 234 | 218 | ||

| Cov ntaub ntawv siv tau ntawm cov khoom ua tiav | haum heev | haum | ||||||||

| tus lej | Cov ntaub ntawv ua tiav | |||||||||

| Cov hlau me HB≤180 | Carbon thiab alloy steels | Pre hardened steel, hardened steel | stainless hlau | nrum hlau | Hlau hlau | aluminium alloy | tshav kub-resisting alloy | |||

| ~ 40 HRC | ~ 50 HRC | ~ 60 HRC | ||||||||

lus hais

1.Qhov kov yog ncaj nraim los ntawm lub neej ntawd.Yog tias koj xav tau lwm cov qauv tuav, thov xa mus rau peb cov ntaub ntawv tuav lossis kos duab rau kev pom zoo;

2. Lub kaum sab xis saum toj kawg nkaus yog 140 lossis 135 degrees.Yog tias xav tau lwm cov ces kaum, thov kos lossis xa mus rau daim duab;

3. Yog tias qhov kev txiav txim tsis sib haum nrog peb lub tuam txhab, koj tuaj yeem qhia peb cov neeg ua haujlwm pabcuam, thiab peb yuav txaus siab los muab cov duab kos rau kev pom zoo rau koj;