Txhua tus neeg ua haujlwm ntxub kev ua txhaum tus kais dej.Tshem tawm cov kais dej yam tsis muaj kev puas tsuaj rau qhov chaw yog ib txoj haujlwm mob.Tsis tas li ntawd, tapping processing belongs rau precision machining thiab feem ntau yog cov txheej txheem kawg ntawm kev ua.Qhov no txhais tau hais tias qhov tawg ntawm tus kais dej tuaj yeem txiav txim siab qhov seem ntawm cov khoom.Tsis suav nrog tus nqi ntawm kev siv ib lub cuab yeej, qhov tsim nyog tus nqi ntawm tapping yuav txiav txim siab tus nqi ntawm cov cuab yeej.Dab tsi yog qhov laj thawj tseem ceeb tuaj yeem ua rau kais tawg nyob ntawd?Yog tias tus kais dej tawg lawm, nws tsis tuaj yeem raug cais tawm hauv qab xya yog vim li cas

1. Xaiv lub qhov hauv qab txoj kab uas hla

Tapping lub qhov hauv qab nrog tus kais dej yuav tsum sib phim qhov loj ntawm lub qhov hauv qab.Feem ntau, qhov sib thooj ntawm qhov ntau thiab tsawg hauv qab yog muab rau hauv phau ntawv teev npe.Thov nco ntsoov tias qhov no yog kev siv ntau yam.Nws yog ib qho tseem ceeb kom paub tias tsis muaj ib qho kais dej thiab xyaum qhov loj me.Rau me ntsis me me threaded qhov, yog hais tias lub torque loj heev, koj yuav tau yooj yim tawg kais.

2. Siv cov kais dej ntau li ntau tau

Tsim tus kaisyog ib tug chip dawb machining txheej txheem uas koom nrog extruding cov khoom ua tiav rau hauv cov duab.Feem ntau yog vim li cas rau cov kais dej yog tias lawv tau thaiv los ntawm lawv tus kheej cov chips, thiab qhov kev nyem ntawm tus kais dej yog tsis yooj yim sua.Lub dov kais kuj muaj thaj tsam loj dua, yog li tus kais dej nws tus kheej muaj zog tshaj qhov txiav kais.

Kev tsim cov kais dej muaj ob qhov tsis zoo.Ua ntej, nws tsis tuaj yeem siv rau cov khoom siv nrog siab hardness li 42HRC.Qhov thib ob, qee qhov kev lag luam tsis tso cai rau kev siv cov kais dej vim tias cov txheej txheem ua tiav yuav tsim cov voids uas cuam tshuam cov pa phem ntawm cov xov.Daim ntawv tapping kuj tuaj yeem ua rau muaj kev ntxhov siab ntxiv ntawm cov xov.

3.Siv lwm yam cuab yeej txiav ua threads

Rau cov khoom siv machining nyuaj lossis cov khoom muaj nqis ntxiv,xov milling cutterstuaj yeem siv tsis yog tapping.

Lub neej kev pab cuam ntawm xov milling cutters ntev dua li ntawm cov kais dej, txawm hais tias qhov txiav ceev ntawm xov mills qeeb dua.Koj tuaj yeem zeb threads ze rau hauv qab ntawm qhov dig muag qhov, thiab ib zaugxov milling cuttertuaj yeem ua cov xov ntawm ntau qhov ntau thiab tsawg.Tsis tas li ntawd, xov milling cutters yog qhov tsim nyog rau kev ua cov ntaub ntawv uas nyuaj dua li cov kais dej.

Rau cov khoom siv ntau tshaj 5.0 HRC, xov milling cutters yuav yog tib txoj kev xaiv.Ntxiv mus, yog tias cov xov mills yuam kev tawg rau hauv lub workpiece, nws tuaj yeem raug tshem tawm yooj yim.Cov xov milling cutter muaj ib lub qhov me dua li qhov machined, yog li nws yuav tsis tawg mus rau hauv ib feem zoo li ib tug kais, uas yog ib qho nyuaj rau lis.

4. Sivspiral flute tapshauv qhov dig muag

Yog tias koj tab tom ua qhov qhov muag tsis pom kev, qhov tsis muaj peev xwm tshem tawm cov chips tuaj yeem yog qhov ua rau kais tawg.Cov ntaub ntawv hlau raug tso tawm mus rau sab saud, yog vim li cas peb siv kauv flute kais, .Tsis tas li ntawd, thov nco ntsoov tias spiral flute kais dej tsis yog qhov cuam tshuam-tiv taus ntau dua cov kais dej thiab pom zoo rau qhov muag qhov muag.

5. Ua tib zoo saib xyuas qhov tob ntawm threading

Thaum twgmachining qhov muag tsis pom qhov, peb qhov kev tawm tswv yim yog ua tib zoo mloog rau qhov tob ntawm qhov muag qhov muag.

Kev ntaus tus kais mus rau hauv qab ntawm lub qhov muag tsis pom qhov yuav luag yuav ua rau tus kais dej.Muaj coob tus neeg tsis paub txog qhov no, yog li koj yuav tsum xam seb yuav tsum tau tshem tawm ntau npaum li cas hauv qab.

6. Xaiv siv cov roj nplua nyeem tshwj xeeb

Feem ntau cov tshuab coolants, tshwj xeeb tshaj yog cov dej-soluble coolants, tsis haum rau tapping vim hais tias lub lubrication ntawm cov roj kuj zoo dua li cov dej.

Yog tias koj ntsib teeb meem ua haujlwm, thov sim siv cov roj nplua nyeem tshwj xeeb.Muab tso rau ib sab ntawm lub tshuab cuab yeej, sau nws nrog lub thawv, thiab qhov program G code kom cia li tso tus kais dej rau hauv lub khob.Xwb, koj tuaj yeem sim txheej kais dej kom ntxiv lubrication los ntawm txheej.

7. Siv cov cuab yeej tapping kom raug (tsuas pom zoo)

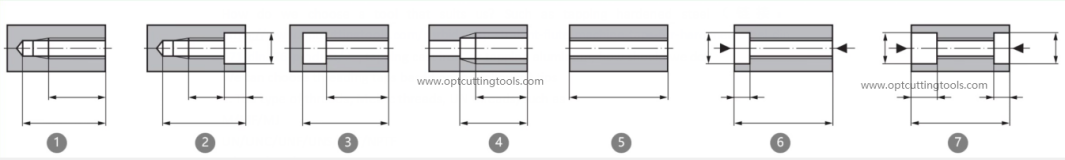

Hais txog tapping tool kov.Ua ntej, siv lub ntsuas phoo txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau nws, nws raug nquahu siv nws yuav tsum tau txiav txim siab).Vim tias tapping yuav tsum muaj ntau lub zog, muaj qhov raug kaw ntawm lub cuab yeej kov yog qhov zoo heev rau tapping.Koj tuaj yeem siv tus kais chuck lossis tshwj xeeb ER kais chuck kom ua tiav qhov no.

Thib ob, txawm tias koj lub cuab yeej txhawb nqa nruj tapping, xav txog cov cuab yeej ntab.Floating tool handles yog qhov tsim nyog thaum tsis muaj tapping nruj, tab sis txawm tias nyob rau hauv cov xwm txheej nruj heev, lawv tuaj yeem txuas lub neej tapping.Qhov no yog vim hais tias lub tshuab cuab yeej raug txwv los ntawm kev nrawm ntawm cov spindle thiab ncej, thiab tsis tuaj yeem synchronize tus kais dej nrog cov xov ua tiav.Ib txwm muaj qee qhov axial quab yuam thawb lossis rub.Floating tool handles tuaj yeem txo qhov kev ntxhov siab los ntawm qhov tsis muaj synchronization.

Zuag qhia tag nrho, cov saum toj no yog 7 lub ntsiab yog vim li cas ua rau kais tawg.Tej zaum cov ntsiab lus peb tau hais tsis tuaj yeem npog tag nrho qhov muaj peev xwm ntawm kais tawg.Txais tos tiv tauj peb rau kev sib tham ntxiv koj machining.

Post lub sij hawm: Oct-17-2023