PCD Tig Grooving Inserts PCD sab nraud grooving inserts pob zeb diamond loj nyiaj xa tuaj groove cuab yeej

Khoom zoo

Kev kho dua tshiab, zoo flatness

Vim tias qhov sib txhuam coefficient raug txo, qhov txiav tsis kam yog txo thiab txiav ntse ntse.Cov ntug txiav muaj qhov hnav tsis kam thiab toughness, siab hardness, siab thermal conductivity, thiab qis thermal expansion coefficient.Lub tshuab nqus tsev vuam riam ntug yog ruaj khov thiab txhim khu kev qha, thiab riam tsis dhia.

PCD piston khoom Sophisticated technology, ntse thiab hnav-resistant

Lub zuag qhia tag nrho hardness ntawm cov hniav yog muaj zog, txiav ntug yog sharper, thiab cov kev pab cuam lub neej ntev dua Cov hniav yog ntse thiab cov kuj yog me me.Txhim khu kev txiav ntug ua rau txiav kom ruaj khov thiab nti tshem tawm sai dua.Cov ntug txiav yog ntse thiab du, hnav-resistant thiab kub-resistant

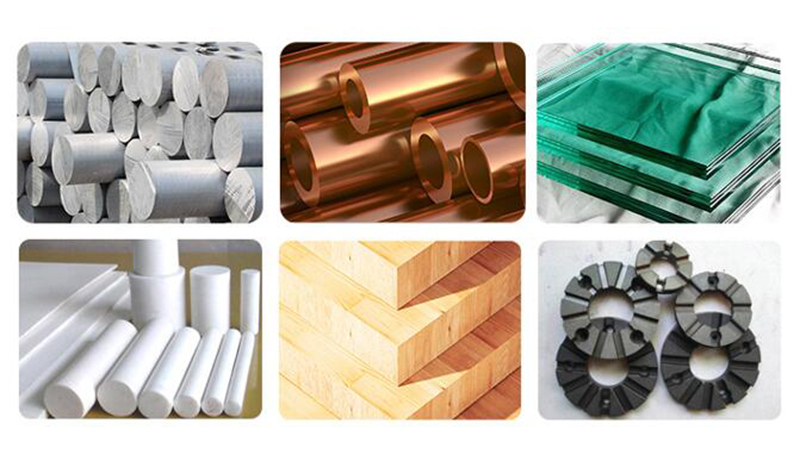

PCD ntxig ntau yam specifications, txhawb customization

Kev nplua nuj specifications thiab qauv, txaus cov khoom muag, txhawb customization.Nws raug nquahu kom paub meej qhov tshwj xeeb ntawm cov hniav ua ntej yuav khoom.Tsis txhob txiav txim qhov loj thiab siv cov hniav tsuas yog los ntawm cov duab.

Smooth txiav yam tsis lo rau lub cuab yeej

Cov ntaub ntawv hlau tsis txhuam nrog cov phab ntsa zawj, qhov smoothness yog ib txwm txhim kho, thiab nws tsis yooj yim rau lo rau lub cuab yeej.Nws muaj cov txiaj ntsig zoo nti tawg thiab nti tshem tawm cov nyhuv, thiab txhim kho lub neej kev pab cuam ntawm lub cuab yeej.

Peb lub PCD grooving cuab yeej rau piston muaj kev xaiv cov khoom nruj

Cov khoom siv zoo nkauj pob zeb diamond yog siv los xyuas kom meej lub neej kev pab cuam ntawm lub cuab yeej.Cov cuab yeej yog ntse thiab hnav-resistant, nrog siab hardness, siab compressive zog, muaj zog thermal conductivity thiab hnav tsis kam.Cov ntaub ntawv ua tiav tuaj yeem ua tiav daim iav nyhuv.Ceev txiav ceev, siab deburring tus nqi ntawm workpiece khoom.

Sab nrauv Grooving Tool siv cov khoom siv zoo nkauj pob zeb diamond, ua tsis muaj deformation

Nws yog refined los ntawm kev xaiv cov pob zeb diamond zoo.Cov cua sov txiav yog yooj yim rau dissipate.Qhov kub ntawm cov hniav yog tsawg.High-efficiency machining hniav yog tsis deformed, hnav-resistant, thiab muaj ib tug ntev kev pab cuam lub neej.

| Hom | Qhov Loj (mm) | Qib | ||||||||

| L | QI.C | S | d | r | PIB 850 | OPT005 | OPTO 10 | OPT302 | ||

| MGMN | 200-02-L ib | 2.0 | 0.2 | 20 | 1.7 | - | ★ | |||

| 300-02-L ib | 2.0 | 0.2 | 20 | 2.3 | - | ★ | ||||

| 400-02-L ib | 4.0 | 0.2 | 20 | 3.3 | - | ★ | ||||

| 500-03-L ib | 5.0 | 0.3 | 25 | 4.1 | - | ★ | ||||

| 600-03 L | 6.0 | 0.3 | 25 | 5.1 | - | ★ | ||||