Carbide kais rau hardened steel Ncaj flute Metric kais, UNC kais

- Khoom piav qhia

Cov kais dej ua los ntawm HSSE lossis HSSE-PM cov ntaub ntawv tsuas yog tsim nyog rau kev ua cov ntaub ntawv nrog lub hardness hauv qab HRC49.Yog li ntawd, rau workpieces sab nraum qhov hardness ntau yam, carbide kais yog qhov kev xaiv ua.

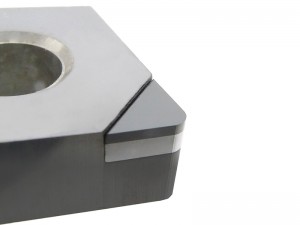

OPT carbide kais rau hardened steel nrog nws tshwj xeeb germery ntawm flute profiles thiab nws tshwj xeeb rake thiab nyem cov ces kaum ua xov txiav hardness steel ntev, nws yog siv rau workpiece hardness ntawm HRC55-63.

TiCN lossis ALTiN yog siv los txhim kho hardness thiab hnav tsis kam txhim kho lub neej ntawm cov cuab yeej.

Raws li cov neeg siv kawg daim ntawv thov, Chamfer daim ntawv tus thawj coj feem ntau tuaj yeem yog 2-3 threads lossis 4-5 threads, feem ntau yog siv rau CNC machining, kais teeb kuj muaj rau kev siv manuel.

- Tej daim ntawv thov

Nyob rau hauv xyoo tas los no, qhov kev thov rau precision machining ntawm cov khoom ua los ntawm hardened steel tau loj hlob exponentially.Kev siv zog ntxiv ntawm cov hlau tawv tawv hauv kev lag luam xws li tsheb, aerospace, thiab kev tsim khoom tsim nyog siv cov cuab yeej tshwj xeeb uas tuaj yeem ua tau zoo rau qib siab hardness.Carbide kais tsim tshwj xeeb rau kev siv steel hlau tau dhau los ua qhov tseem ceeb hauv qhov no.

Nws yog ib qho tseem ceeb uas yuav tau xaiv cov khoom siv carbide tsim nyog rau txhua daim ntawv thov tshwj xeeb.

OPT tau cog lus rau xov machining nyob rau hauv ntau yam kev lag luam, raws li tus neeg siv daim ntawv thov txuam machining kev daws teeb meem, coj cov neeg muas zaub zoo dua ua tau zoo thiab ntau lawm efficiency.

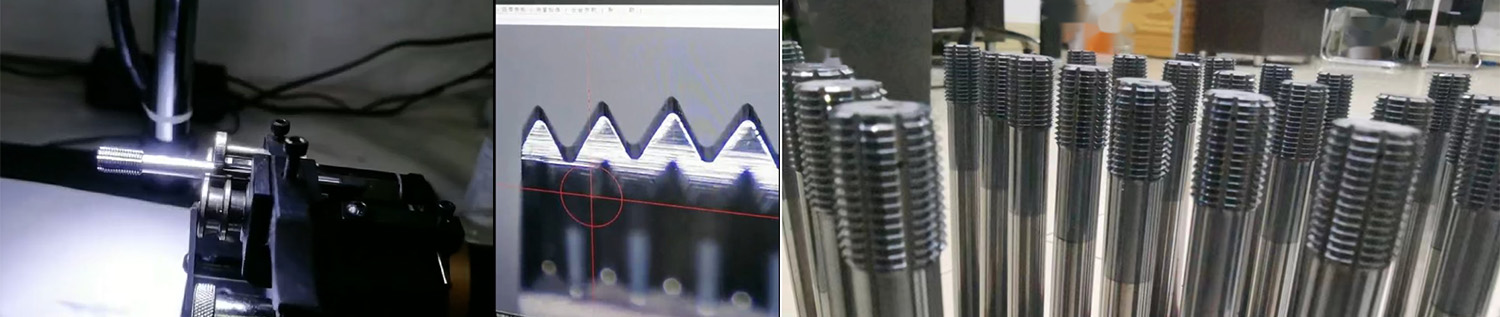

Kev tshuaj xyuas thiab tso saib

Ua ntej xaj, thov sib txuas lus nrog peb cov neeg siv khoom ua ntej muag:

1. Cov khoom siv ua haujlwm

2. Seb cov khoom puas raug kho tom qab ua tiav

3. Qhov yuav tsum tau muaj qhov tseeb, qhov loj ntawm qhov ntsuas mus thiab tsis muaj qhov ntsuas mus.